RHD HOME MARKET TR8 NWK988W

I’ve known about this RHD TR8 NWK988W for about 30 years or so after an ex-manager at Canley/Solihull (Garry Owen) responsible for the RHD TR8 project gave me a collection of some memos and other documentation on the car for my TR8 website. Once I learned of its unique history at BL Motorsport/Special tunning Abingdon, it quickly became the “ONLY RHD” TR8 I ever wanted to find. March 2022 I was incredibly fortunate and lucky enough, to be finally able to buy this very unique “HOLY GRAIL” of the 22 RHD TR8’s if you will. While it is rare enough in being 1 of only 22 RHD TR8’s the factory ever built, it is also rarer still in being 1 of 1 in that it is the only one ever modified and tuned by BL Motorsport/Special Tuning at Abingdon. In particular by two of Tony Ponds 1980 rally team, Cliff Humphreys for the engine modifications and Richard Hurdwell for the suspension. It is the most powerful and best handling road going TR8 the factory ever made, hitting 150mph on a test run. Sadly the one, and only one, ever made to this specification; but it was a great note to end on, as production sadly ended October 5th 1981. Development continued on this car as it was the future development RHD TR8 right to the end of July 1981, (from June that was down to it being Richard Hurdwell’s company car at the time, so unofficially for the last month, as he personally wanted to finish the car) with that being well after the last batch of 9 marketing cars that were built earlier in the year in March 1981, it represents the very last built/worked on RHD TR8 version the factory ever made. More information on the 22 RHD TR8’s is HERE

And yes “TONY POND” and other Rally personalities have driven this car during its time at Abingdon, but only to the shops or the pub as a pool car while it was there being worked on, more so as it was Tony’s team doing the work on it.

When the decision was taken to close the TR7/8 production down as BL couldn’t make it work financially, the factory had a big sell off of the RHD TR8’s and various other development cars at Measham August to September 1981 – NWK988W can be seen in this video at around 02.10. It sold for around 12k to its first owner.

Make Triumph

Model TR8

Engine 3528cc, V8

Power 270bhp @ 5800rpm @ the wheels

(rolling road test September 2023 , approximately 300bhp at flywheel)

(STD RHD TR8 153bhp @ 5250rpm – minus 117bhp)

(STD Carb LHD TR8 133bhp @ 5000rpm – minus 137bhp)

Torque 301lb ft @ 4600rpm

(STD RHD TR8 197lb ft @ 2500rpm – minus 104lb ft)

(STD Carb LHD TR8 168lb ft @ 3000rpm – minus 133lb ft)

Top speed 150mph

(STD RHD TR8 130mph – minus 20mph)

0-60mph 5.6 seconds

(STD LHD/RHD TR8 8.1/8.6 secs – minus 2.5/3.0 secs)

Consumption 28mpg (average round Britain run 2023)

Gearbox Five-speed manual

This car in its life had in effect two engine builds the FIRST being to what would later become the 20E engine and the SECOND to what was essentially a Vitesse engine with WL9 cam which would have been the engine of the PRODUCTION RHD TR8’s had they launched with what ever engine number that would have been (30E?). Performance run below in September 2023 gives plus 270bhp at the wheels as we clocked the road to its limit. Estimate would have been around 300bhp at the flywheel when the factory had the car.

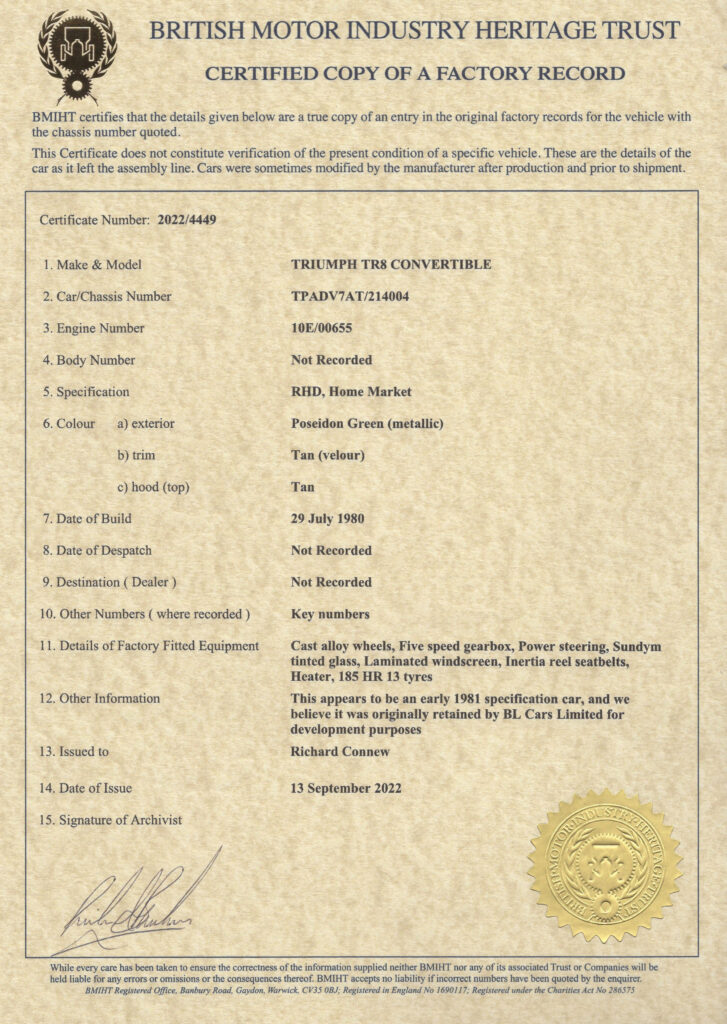

Heritage proof of genuine factory RHD TR8

This TR8 is unique in that it was the most heavily modified TR8 ever built by the factory and was clocked at 150mph on a test run in early 1981. NWK988W was used as the UK RHD TR8 Development car to present alternative engine and chassis specifications for the future UK and European Sports Car Market. That work was done by Tony Ponds 1980 TR7V8 works team, Cliff Humphreys for the engine modifications and Richard Hurdwell for the suspension down at BL Motor Sport Abingdon. John Davenport (Head of BL Motorsport at Abingdon) remembers the car being at Abingdon and quoted it as being a hybrid Rally/Road car built to see how far the road car could be pushed. The final version of this car was indeed a hybrid Rally/Road car with Peter Wilson an ex-engineering consultant at BL recently saying if they had known what was going on, it would have never been built! Probably why it was moved down to Abingdon and BL engineering were kept out of it, so are not copied on the memo. Actual Memo from BL MOTORSPORT at Abingdon detail the first round of modifications. There were later modifications made in 1981 but they aren’t documented.

BL MOTORSPORT MEMO

Dated Dec 16th 1980 detailing some of the many changes made to the car; the majority if not all of these changes are still on the car plus a few more.

CC: MR G OWEN

SOLIHULL

Fi: MR J DAVENPORT, MR D WOOD

TR8 MODIFICATIONS

PURPOSE

A green TR8 (NWK988W) from Solihull has been subject to both engine and suspension modifications at BL Motorsport Abingdon. The purpose of this was to present alternative engine and chassis specifications for the future UK and European Sports Car Market.

ENGINE MODIFICATIONS

All following modifications were carried out on a standard TR8 V8 unit as fitted in test vehicle.

- Compression ratio initially raised to 9.35:1 by fitting current SD1 V8 pistons.(More recent engine information/testing says it now runs 9:75:1 pistons due to the performance it puts out – 270bhp – and further evidence from the time stating all of the factory 20 x car WL9 cam conversions – of which this car was one – used 9:75:1 pistons.

- Standard camshaft replaced by ‘WL9’ Motorsport camshaft and valve spring assemblies.

3. Zenith-Stromberg carburettor fitted with alternative fuel control needle to suit ‘WL9’ camshaft.

The engine will be tested on the rolling road in Jan when it returns to Abingdon with more running-in completed.

CHASSIS M0DIFICATIONS

The following modifications have been carried out so far and are felt to have improved the car. Final ‘tuning’ of our proposed specification will be made in Jan 1981 after initial comments from Solihull test mileage.

FRONT BRAKES

A Ventilated Brake Disc Kit was fitted using Ferodo DS11 pads this has improved the standard braking significantly and is virtually fade-free from repeated high-speed stops. The kit was developed by Brian Owen at Abingdon in conjunction with John Moore at Automotive Products (Racing) Leamington.

Automotive Products would be able to supply in quantity.

These brakes will only fit the car with Alloy wheels.

FRONT SPOILER

A works rally TR7 V8 spoiler was fitted, with small modifications to fit under the bumper. This is a GRP moulding made for us by Albert Coates in John Cooper’s ‘Plastics Development’ area at Solihull.

The spoiler has proved very robust, but for extra durability a flexible polyurethane moulding was planned for the (now scrapped) 1981 rally TR8.

Wind tunnel testing at MIRA during rally car development indicated that this spoiler should reduce front lift by between 10 and 30%. This assists straight line and cross wind stability which was found to be a problem. Engine cooling should also be improved.

(On the under rear side the red gel colouring for the works TR7V8 rally cars can still be seen indicating it originally came from the works stock)

Wind tunnel testing at MIRA during rally car development indicated that this spoiler should reduce front lift by between 10 and 30%.

FRONT SPRINGS

These were as set up for the 1979 Donnington Rally sprint cars i.e.TKC 3088 (blue) springs lowered 25 mm by heating one coil. Actual spring specification will be established by removal and measurement in Jan. A properly made and heat-treated pair will be made for final presentation. A further 10 mm reduction of trim height is envisaged for this final presentation.

FRONT DAMPER INSERTS

The standard car seems to suffer from under damping especially on rebound. This causes a large amount of pitch over bumps even on ‘smooth’ motorways and causes large variation of tyre/ ground contact force.

Dampers with approximately 25% more bump and 50% more rebound £force were considered but since we had already units with 25 and 100% extra these have been fitted at present. Armstrong are willing to make a set of trial units to our specification.

FRONT SUSPENSION

The standard car suffers badly from nosedive under braking which is uncomfortable, reduces braking stability and causes large variations in headlight range. To reduce this an extra packing piece UKC 9883 is fitted between roll bar clamp ~ sub frame. The standard bolt is long enough to allow this. UKC 9883 does not appear in our parts lists but seems to be fitted on the cars. The proposed extra reduction in trim height will further reduce brake dive.

The standard car also suffers badly from compliance in the track control arm/roll bar joint. To reduce TCA movement and caster change under braking, a hard polypropylene bush is used behind the TCA. This is similar to the standard part UKC 208 but with approximately 70 shore hardness. This modification also greatly assists straight-line stability as there is considerable fore/aft motion of the wheel over bumps.

Rally experience shows that a completely revised joint giving far less compliance would provide very significant improvements in handling and braking. It is not anticipated that this would give a large increase in road noise transmitted to the body since there is already rubber in the roll bar and TCA transmission paths to the sub frame, which itself is rubber mounted to the body.

STEERING

No changes have been made in this area but bump steer checks will be carried out before final presentation. My personal impression of the steering is that it gives a very good balance between steering effort and feel which suits the car well. Steering ratio is good for road use.

Congratulations to whoever developed this.

REAR SPRINGS

The first set of springs tried were TKC 2404 lowered by approximately 25 mm. These worked well but have settled further and given problems of bottoming on the bump stops.

The springs originally fitted were then lowered by 25 mm, and subsequently by a further 12 mm. These seem to have a higher rate than the first set but the MG closure has temporarily left us without testing facilities.

As with the Front Springs a properly made and heat-treated pair of springs will be fitted for final evaluation.

REAR SHOCK ABSORBERS

The standard units seem to be about right on bump setting but, as the front, lack rebound capacity. Some adjustable units have been fitted to the rear and are set to give a good compromise between ride and handling.

The bump setting at the rear has a very great effect on ride comfort, the occupants being close to the rear axle and any large increase over standard bump makes the ride harsh.

Armstrong are willing to make a set of trial units, testing the adjustable units to arrive at the required setting.

REAR SUSPENSION

To reduce compliance (and hence steer and tramp) the ‘windowed’ lower link bush has been replaced by standard Dolomite and

TR7 Part 149827. The 4 upper link bushes have been replaced

by Motorsport tuning parts for Dolomite – Part No STR 0018.

These bushes are similar to the standard bush but with shore hardness increased from 45 to approx. 65-70.

Stiffening the bushes does not seem to give an unacceptable

increase in transmitted noise – especially in this soft top version.

The mounting in the body for the lower trailing link has been raised by 25 mm. This considerably reduces the rear end ‘squat’ which is very evident on acceleration in the standard car. Traction is considerably improved and the standard tendency for axle tramp is reduced.

(The upper mounting was also moved 25mm and the rear anti roll bar was removed- but this was done later than this memo was written, most likely in early January 1981)

REAR BRAKES

Alternative brake lining material (VG 95) was fitted to reduce fade. This material is readily available from Ferodo.

TYRES

The car was fitted with 185-70/13 Goodyear tyres. These do not give particularly good grip, especially in the wet. From our experience with Michelin TRX tyres these can give improved ride as well as cornering power. The ride properties of the tyre would help to counterbalance any extra harshness from stiffer suspension. The extra handling performance will enhance the car’s already high cornering power and make it safer.

John Re at Canley has or will have some fabricated wheels to try TRX tyres on a TR7 but they may not fit on the ventilated brake hubs. Michelin are to provide some suitable wheels and tyres in late Jan for test purposes.

Contact at Michelin – Dave Taylor (0782 48101 Ext 241).

Richard Hurdwell Engineering Liaison

RH/AM

To quote the late Rex Holford (TR8 Archivist)

“From the attached document (BL MOTORSPORT memo) You will see that RHD TR8 NWK988W has been modified, but in such a way that it would be the forerunner of the 1982 spec TR8s”

The Team at BL MOTORSPORT ABINGDON who worked on the car were

NWK988W engine was modified by Development Engineer Cliff Humphreys

From a standard 10E federal spec TR8 engine it was initially Increased to 9:35:1 compression. Later it had added the BL MOTORSPORT WL9 camshaft modified Stromberg’s and further in line valve and spring modifications to increase performance. (More recent engine information/testing says that the car actually now runs 9:75:1 pistons due to the performance it puts out – 270bhp. Further evidence from the time stating all of the factory 20 x car WL9 cam conversions – of which this car was one – used 9:75:1 pistons further supports this)

NWK988W suspension was modified by Development Engineer Richard Hurdwell

Rally front spoiler, Front vented disks, rear brakes improved, lowered and strengthened suspension throughout.

Both engineers were part of Tony Ponds works rally team for 1980. This is the only road going TR8 ever worked on by the works team at Abingdon. Given the further development they made on the car (right up to not long before the car was sold at Measham auctions 7th August 1981 – because it was Richard Hurdwell’s car at the time so unofficially it continued a bit) it’s true to say this RHD TR8 is the most advanced for the future RHD TR8 BL ever made.

Works Drivers

As it was Tony Pond’s team building and modifying the car did Tony Pond ever drive it? Yes, but never in anger in a race/rally, just down to the shops or the pub as while it was being worked on at Abingdon, it was regarded as a pool car when required; so many such BL Motorsport personalities at Abingdon in 1980 would have driven it.

Management

John Davenport remembers the car and described it as a hybrid they built to see what the road car could be made to do.

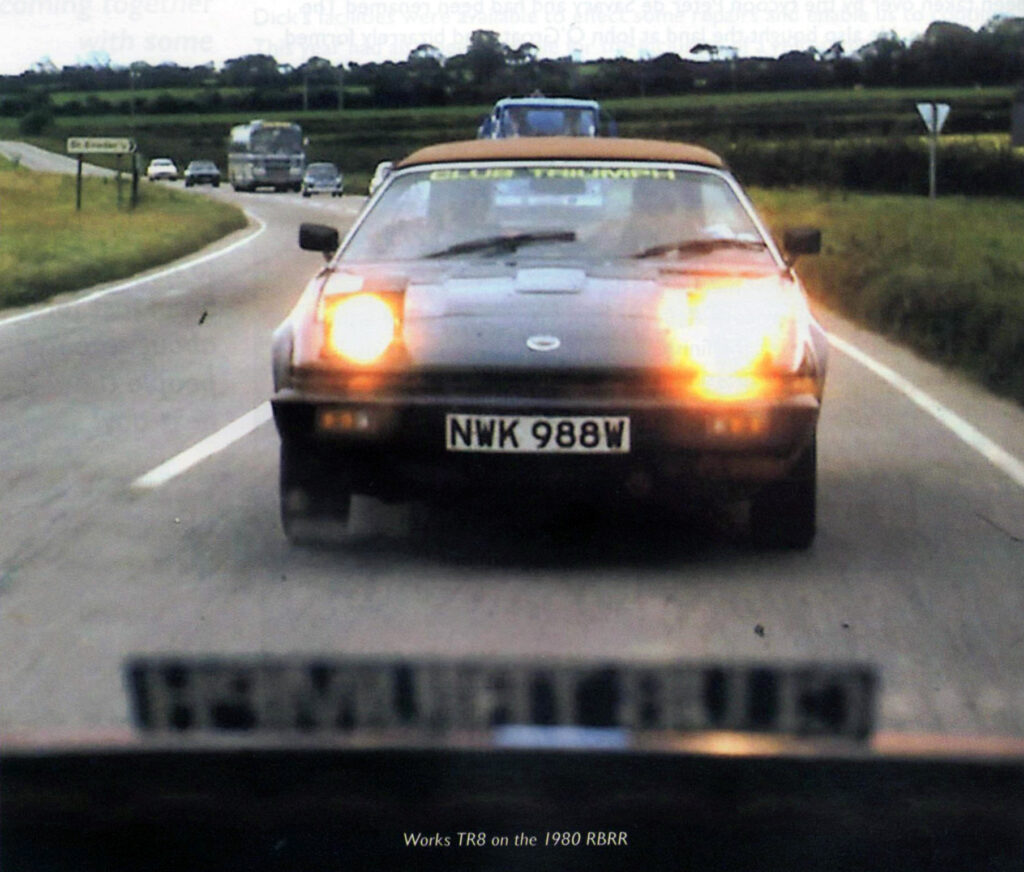

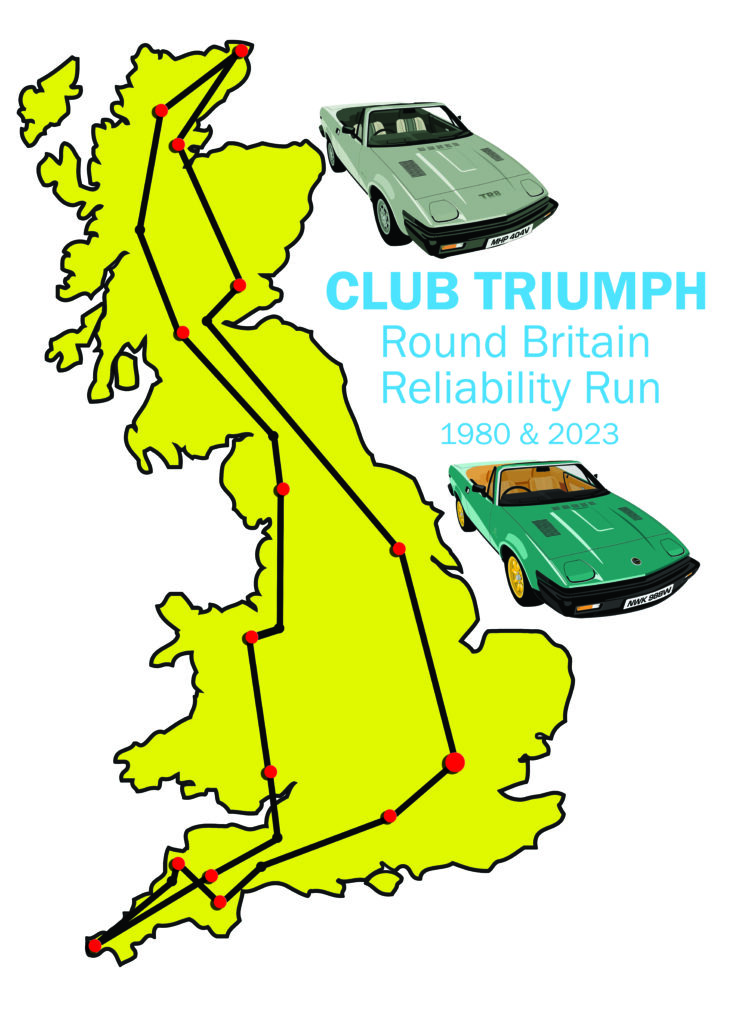

ROUND BRITAIN RALLY 1980

The car was used by the factory on the Round Britain Rally in 1980 along with a Silver TR8 MHP404V. At the time it was done there had been no decision to not

launch in the UK and it was still an active project. The tour was through the Triumph Club in London and it was setting off on a Friday night up to “John O’Groats” then “Lands’ End” and back to London on the Sunday night. It was done with the intention of getting some publicity for the RHD TR8 yet to be launched in the UK, and for club members to see the cars.

Rover Triumph Plant Director John Micklewright and Transport Manager Bob Train having a break. Silver TR8 MHP404V driven by Group Manufacturing Director Brian Fox and Bob Train.

Rover Triumph Plant Director John Micklewright and Triumph Factory Manager Gary Owen (asleep) driving NWK988W.

Rover Triumph Plant Director John Micklewright and Triumph Factory Manager Gary Owen driving NWK988W

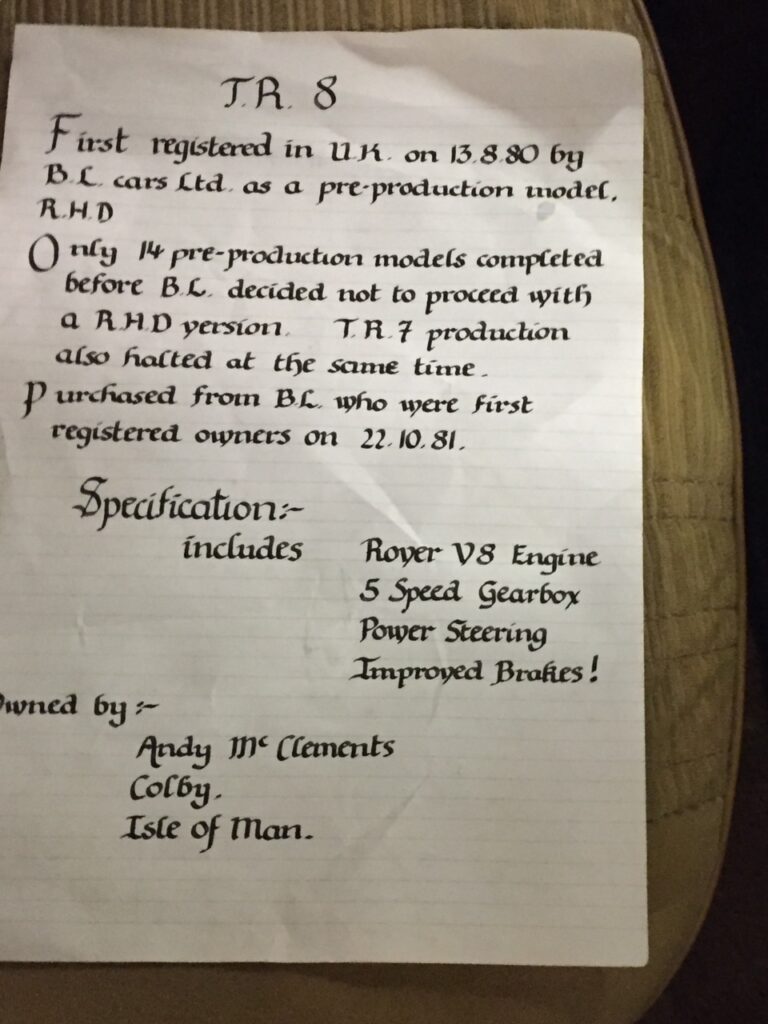

Practical Classics September 1997

It turns out the first owner who had it on the Isle of Man for 40 years hidden away in his collection didn’t actually know just how special the car was, he thought the only things different were the brakes! First owners’ information sheet for the car. He also has the number of RHD TR8’s incorrect, as there are 22! But there were 14 unregistered RHD TR8’s sold at Measham which is where that figure comes from. The other 8 were either already registered (3) as in NWK988W, MHP404V, RDU35W and in the auction, so total RHD TR8’s in the auction was actually 17, with another (5) registered/unregistered sold privately by BL to preferred dealers.

NWK 988W Owners and continued history

At the time I talked to the ex-manager no one was sure where it was and or went after it was sold at the Measham auctions in 1981. Richard Hurdwell told me he wanted to buy the car himself but it was sadly outside his budget at the time. NWK988W appears a short way into this video of Measham Auctions at about 0.26

It wasn’t until about 10 years or so later, I found out NWK866W was on the IOM with Andy McClements (Owned for 38 years) of Colby an amateur Rally Driver, who also kept a collection of interesting sporting cars. He sadly died in 2015 and his family sent the car to the local garage to get it running again ready for sale.

There was a period of time where I understand the family wanted Andy’s car collection to go as a job lot, however that wasn’t to be. The family then approached Mervyn Johnston in Co Fermanagh N.I.to ask for help in selling the car. Mervyn too was a good Rally Driver (Mostly Mini Coopers) and frequently stayed with Andy during rallies on the IOM as they were close friends. In the end Mervyn bought the car himself 28/10/19 and took the car home to Northern Ireland (Owned for 1.3 years). Sadly, he was struck down by illness not long after getting the car so it wasn’t driven for another year and a bit before being sold to William John Ferguson (Billy) (Owned for 1.1 years) 12/2/21 who had been told about the car. Billy being 86 found the car difficult to get in and out of so he put the car up for sale in his local auction.

Essentially a farmer’s auction in a remote part of N.I. Fortunately for me as part of my interest in TR8’s I run various programmes that search out TR8’s for sale and this one came up in my auto feed. So, on 19/3/22 the car came into my possession and arrived in North Yorkshire on the 24th due to ferry problems preventing us getting it across sooner.

Because I’ve known its history and spoke to the ex-manager at Solihull at length many years ago, I already knew quite a lot about the car. A small part of that in the memo – above – (registration number I removed on the web site) I posted on the web site I had at the time, needless to say it was “borrowed” and has appeared in a lot of places since! Richard Hurdwell who worked on the car is fortunately still alive and I’ve been lucky enough to be able to talk to him at length about the car. Once the car is recommissioned properly, I arranged to meet up at Gaydon to let him drive the car again as it was sort of used as his company car at the time, to allow him to make running suspension improvements as he drove the car.

The car has been worked through from March to July 2022 replacing as needed as it has essentially been unloved with no to any maintenance for many years, less the wheels, which were powder coated by the last owner to such a thick level I had to use blocks of wood, large hammers, and driving the car with wheel nuts loose to break the wheels free. Its now running on a set of Gold Minilites 15” with low profile tyres. The original wheels will be blasted and coated correctly and so they can if required, be put back on at a later date. Personally, I prefer GOLD with Green but that’s me. Some early TR8 development cars were fitted with gold wheels. More work has continued on the car to the present day trying to undo previous owners “mistakes” to get the car running again as well as it did when the factory owned it. Still a few minor issues to resolve but it is pretty much there now just over a year after I got NWK988W.

When NWK988W first arrived with me in March 2022 it’s mileage was just 18,171 from new!

Approximately 20K has been spent on the TR8 getting it back to running condition. Many parts have been reconditioned due to corrosion and new parts fitted where needed, full fluids change throughout the car etc etc.

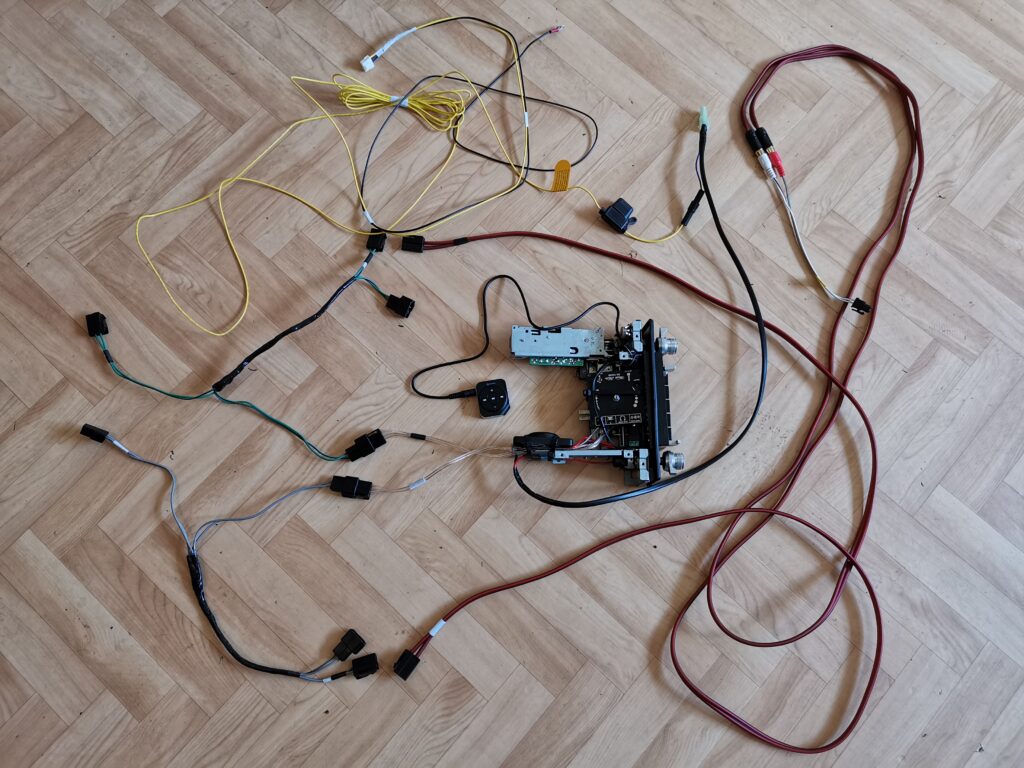

Some of the parts changed replaced etc

Carbs rebuild with new parts. Needles were soldered/bodged replace with new rich running needles at best guess to what the originals would have been, as due to the solder it was impossible to tell what they were when BL Motorsport modified them. Eventually we found a rich enough needle for the car B24081 which is the richest needle still made by Stromberg. Complete rebuild and tune carbs accordingly. SU needle bodged to fit wouldn’t allow the car go past 70-mph.

Repair auto choke

Re-paint inlet manifold original grey

All new gaskets for Carbs including remake one gasket no longer available.

Fuel cap replace with new vented, old gummed up and not working causing vacuum in tank and poor running.

Air filters replace (K&N)

Badly powder coated Alloy wheels replace (15” GOLD Minilites)

Tyres replaced to low profile

Gearbox remote bushes all fallen out / DISINTIGRATED! replace all 8.

Air box’s corroded refurbish

Exhaust hot air corroded refurbish

Exhaust system replaced with new stainless steel.

Heat hose and Cool hoses replace with new

Coolant header and bracket corroded refurnish

Coolant sensor replace

Thermostat for coolant replace

Rockers corroded refurbish

Water pipes replace with new

Pipe clips replace as required

Oil replaced with new

Coolant replaced with new

Spark Plugs replace (Iridium)

Coil replaced

HT Leads replace

Rotor arm replace

Gearbox replace broken selector frame on stick

Fit Steering bush DISINTIGRATED!

Adjust Distributor timing and advance curve

Fuel pump replace with external and add regulator as originals gummed up with old fuel.

Track rod end replace

Tracking adjusted

Power steering belt replace

Alternator belt replace

Starter motor replace

Clutch master cylinder replaced and use shorter fork

Clutch slave cylinder replaced

Clutch pipe replaced with braided one

Battery replaced with O72 Lucas

Wiper blades

Repair Gear gator and replace top rubber part

Replace incorrect screws in door locks and line up correctly

Replace screws in door releases

Replace damaged knee pad

Replace damaged heater knob

Fit missing TR8 Glove box badge

Heavy duty clean Interior

Heavy duty clean carpets

Repair minor hood damage

Repair seat belts

Ns door mirror

Repair and re-paint front works spoiler

Quarter lights rusty re-paint new seals

Doors new seals window

Source Buff NOS badges/decals

Handles new seals

Rear lights new seals

Weather protect underside – Lanoguard as its clear so mods can be seen.

Lights replace all with LED!

Wiper motor

Ball joints

Track rod ends

Steering bushes

BARE MINIMAL- BLOW OVER RE-PAINT for the car as it had about two or three different shades of Green

An outer main panel bare minimal “ONLY” green paint job to preserve its originality as much as reasonably possible, has been done while trying to match the original paint look/finish as opposed to making the car look concours. Given while at a distance the paint looked great, close up it wasn’t. It possibly had 2 or 3 different shades of GREEN on the car. The differences in paint can perhaps be best seen with the next picture in particular the passenger door shade of green against the wings.

On painting it was found to have a very large dent in the passenger door that had been badly filled and painted. This thick pad of filler was removed and the door dent pulled out and repaired correctly. To repair this correctly required a back to bare metal for the door.

The front panel was also found to have been damaged at some time. A very bare minimalist blow over paint job along with the various widespread dents fixing was done, to get everything to match correctly while still preserving as much of the original paint as possible. None of the black areas and ancillaries were painted at all, as well as under bonnet, engine area, inner door, windscreen and boot areas.

Back from the Paint shop and as NWK is currently with Minilite wheels in gold

Fit a NEW/OLD STEREO – car still had the black cubby box with no stereo ever fitted. Retro system fitted – Looks 1980 period Pioneer facia but behind is a modern 50-watt amp and USB and Bluetooth system. Speakers and Tune-ups are period 80’s NOS. The sub-woofer fitted under the passenger seat is a new Pioneer Sub as I couldn’t track a NOS one down.

(LATER the Bluetooth amps were found to be just not be up to the job for multi speakers, so a modern minimal Pioneer stereo was fitted)

It was important to keep the car looking period so everything that can be seen is circa 1980. The modern Bluetooth amp is hidden behind the Pioneer KP-5800 fascia

DIFFERENCES FOUND ON NWK

There are a number of differences on this car over other RHD TR8’s, these are some of the main ones,

Works spoiler fitted for up to 30% lift reduction – The spoiler is still RED fibreglass behind so you can see it came from works stock originally, before being painted black to match the car style.

Battery tray cut away to allow easy access

Efi Breather system instead of the normal pipe across to the other carb

Radiator No 2? Various exp items were tried out on the car.

Chassis Plate USA type but fitted in correct UK position with UK RHD Chassis number

H4 Headlights – Marked Blue logo on light – Inside has a dish element.

Vented Disk Brakes plus various other suspension modifications

Engine when I got it had a lot of corroded parts and worn pipes along with flaking paint

After powder coating and new pipes etc

Engine is fitted uniquely with the WL9 BL MOTORSORT CAMSHAFT and appropriate valve spring assemblies.

Former ARG Motorsport Director John Davenport disclosed that the WL9 cam was developed by the Motorsport division and fitted to around twenty of the company’s own cars (NWK988W was among these and the only road going TR8 fitted with one) and a few clients’ vehicles. ARG’s Engineering Division also fitted some WL9 cams to engines for testing as assessment, (Pictures of WL9 are from one of those engines that I was lucky enough to get hold of as a spare) but it was never accepted for full scale production. As it was not a required part of the homologation regulations for the ETCC race cars, it did not need to be fitted to the road-going cars.

The bare figures are 19/57/57/19 = 256 deg period, 435/.430 valve lift with 1.6 rockers. That doesn’t tell the whole story, of course, as the secret is in the steep opening and closing ramps. It was the cam homologated for the later racing Vitesse’s, but only fitted to about 10 actual production cars. The earlier Group A racing Sd1s were limited to the .390 standard lift, so it is likely that BL actually developed the WL series for the TR8 initially moving to SD1’s after the TR8 programme ended.

Body plate is the CHP 300 series.

Only used on the RHD HOME MARKET TR8’s. this is the lowest in the 300 series known. It is the second RHD TR8 built. Earliest known CHP body number.

NWK988W for 1980/81 was one a hell of a car, and it isn’t slow by today’s standards either.

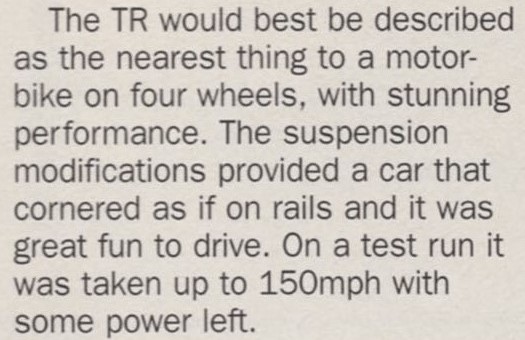

Handling is the best of any TR8 I’ve ever driven, like it’s on rails, and as Gary Owen Triumph Factory Manager at Canley, said in his letter in September 1997 Practical Classis it’s a “DREAM DRIVE”

At least this TR8 survived so we now know what might have been. It would/could potentially have been the spec for the 1982 RHD TR8s so it is as such, “The very last specification factory RHD TR8” And what a GREAT note to end on! End of production was announced in the USA on May 14th 1981 with the last cars rolling off the production line in October 1981.

PERFORMANCE CLAIMS NWK988W

In his letter to Practical Classics in September 1997 Garry Owen Manager responsible for the RHD TR8’s stated the car achieved 150mph.

I have in 2022 spoken to Garry personally where he again stated 150mph. Sadly the data from the rolling road test Richard Hurdwell mentioned in his December memo 1980 “The engine will be tested on the rolling road in Jan when it returns to Abingdon with more running-in completed” no longer exists. We do know however due to a rolling road test we did September 2023 with the car it reached 270bhp at 5.8k rpm.

So, as I am unlikely to risk damaging such a unique car getting it to 150mph again after so many years, what do we know for sure is on paper, it is easily doable. Car reaches maximum power of 270bhp at 5.8k plus but will easily rev to 6k plus.

| TR8 UK SPEC | 80/81 | |

| Miles 5th Gear | Revs K | MPH |

| 27.6 | 1 | 27.6 |

| 2 | 55.2 | |

| 3 | 82.8 | |

| 4 | 110.4 | |

| 5 | 138 | |

| RED LINE | 5.5 | 151.8 |

| 6 | 165.6 |

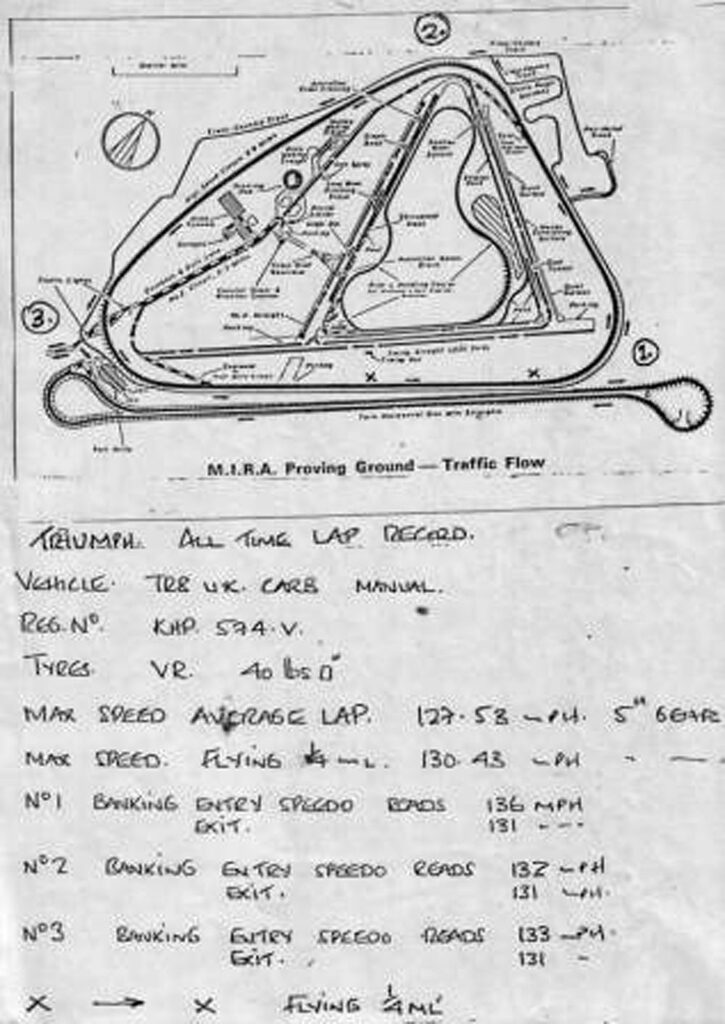

Given the normal engine redlines at 5.5k the maximum theoretically would be 151.8 mph however with this cam we can go to over 6k. For a standard car much more than 5.5k and the hydraulic lifters run out of oomph and you have to back off the throttle for the engine to run correctly. In effect they pretty much run as a speed limiter, so it’s not possible with the standard engine setup/cam. That is borne out by TR8 X923 (USA 13E engine – modified to 9:35?) speed tested at Mira to 130.4mph flying quarter mile (top speed very briefly 137mph) with most likely the same 5th gear ratio. X923 didn’t have enough power or revs for more and nor was it likely to have been very stable at its maximum, although it does have the earlier MK1 works spoiler fitted.

Stability

Having driven a modified TR7V8 200 bhp on the Autobahn many years ago on a long straight heading south from Hamburg early one Sunday morning I can attest unless you have a death wish 130mph with the standard spoiler/suspension setup is about the absolute limit. Maybe I could have gone a bit more, but I decided that was more than enough excitement for one day.

A close friend and TR7/8 engineer did take on the Autobahn a modified TR7V8 200bhp plus car that had a high lift cam fitted (allowing revs to 6.5k) along with the later works tarmac MK2 spoiler fitted, and got the needle right round the clock to the P at the bottom of the cloc,.so in theory past 150mph.

Fitting the tarmac or MK2 spoiler RE Richard Hurdwells memo “Wind tunnel testing at MIRA during rally car development indicated that this spoiler should reduce front lift by between 10 and 30%” so you are going to need that fitted or the car will be too unstable at high speed. It is fitted to NWK988W.

NWK988W Engine

Sadly, after so much time we only know the following about the engine from the memo Richard Hurdwell wrote Dec 1980. (Rolling road tested September 2023 to 270bhp)

“1. Compression ratio raised from 8.13:1 to 9.35:1 by fitting current SD1 V8 pistons. (Believed later changed to 9:75:1)

2. Standard camshaft replaced by ‘WL9’ Motorsport camshaft with valve and spring upgrade assemblies.

3. Zenith-Stromberg carburettor fitted with alternative fuel control needle to suit ‘WL9’ camshaft.”

On talking to Richard Hurdwell about the engine; when he wrote the memo, he only knew the basics of what was done to the engine. More work was likely done he said, he just didn’t know what, as all the engine gearbox work etc was completed before he was given the car. Axle ratio could have also been changed to 2.84 for example to give 33 per 1K revs, but in the absence of any proof we will assume not. The 5th gear ratio could have also been changed, but again no proof so we assume not. What we do know however, is that for the run NWK was on different wheels and different high-speed tyres Michelin TRX (metric – first available low-profile tyres).

From Richard Hurdwell Dec 1980 MEMO “From our experience with Michelin TRX tyres these can give improved ride as well as cornering power. The ride properties of the tyre would help to counterbalance any extra harshness from stiffer suspension. The extra handling performance will enhance the car’s already high cornering power and make it safer. John Re at Canley has or will have some fabricated wheels to try TRX tyres on a TR7 but they will not fit on the ventilated brake hubs. Michelin are to provide some suitable wheels and tyres in late Jan for test purposes.”

They were larger than the standard wheel/tyre approximately 15” to clear the vented disk brakes, and thus changed the ratio that way, increasing actual mph. Average on a selection of available likely TRX tyre sizes on, was between 7 to 9 miles plus over

standard wheels tyres at 140mph. A larger wheel from Michelin was required to clear the vented disk kit fitted to the car as per RH memo. The TRX tyre could only be mounted on TRX wheels and they were conceived to work as a unit from the start, TRX wheels are built in metric sizes instead of inches and the inner shape of the wheel is different than regular J-type imperial wheels. So that is most likely the missing ratio piece of the 150mph puzzle. To achieve 150mph again, the current wheels/tyres would likely need to be changed. NWK currently has 15” with 195/50 fitted. Standard was 13” 185/70.

Conclusion

- What we do know is the WL9 cam fitted to the car with valve mods will allow revs 6K plus, so reaching 150mph with the gearbox and 3.08 axle ratio is certainly achievable. More so with larger wheels and tyres increasing the miles per turn over standard. Maximum power we now know after testing on a Rolling road September 2023 is 270 bhp at the wheels so more than enough for such a small light car. It is also believed the car actually has 9:75:1 pistons fitted probably done at the same time as WL9 cam.

- With increased stability due to the Richard Hurdwell handling package and tarmac spoiler fitted, the car is more than stable enough to hit 150mph.

TR8 X923 very briefly reached 137mph with a much less powerful engine (minus 117 bhp) and no WL9 CAM fitted for higher revs. So could NWK988W with considerably more power and higher revs get the extra 13mph over X923. BL Engineering dept put X923’s engine together and BL Motorsport Abingdon put NWK988W’s engine together; so, Abingdon’s version would also have a lot more inherent performance knowhow engineered into the car than BL. With a road long enough a 150mph maximum speed for NWK988W is correct. The fact it was said with “some power left” seemed a tad optimistic at first, unless of course the ratio was changed in some way as well, and that was the case at the time with larger wheels and tyres.

Going forward

June 10th 2022 Gaydon. Richard Hurdwell (Suspension Engineer on the car) turned up to look his old car over again and close a chapter for him. It was a privilege to take him for a drive in the car.

August 20th 2022 TR Register Event Derby – NWK988W won the survivor’s cup.

November 13th 2022 TR Register stand NEC Birmingham Classic Car Show

November 13th 2022 TR Register stand Richard Hurdwell for his second visit of the year.

Mileage for NWK988W in March 2023 was just 18,411 from new! Only a few hundred miles from when I first got it because it had taken so long to get the car running correctly again.

NWK988W further tuning 2023

When the car arrived the maximum speed, it would do was 70mph then it ran out of fuel! So, I send the carbs away to be completely rebuilt. There were many, many faults, auto chokes blocked up, floats in upside down, SU needles fitted and soldered up, to name just the main ones.

So for 2022 just getting the car running was the priority. There was unfortunately no refence to what needles the factory used,

“Zenith-Stromberg carburettor fitted with alternative fuel control needle to suit ‘WL9’ camshaft”

so, to start we had no choice than to put the standard North American TR8 ones in which are B1EM and for 2022 it ran fine for what I needed it to do. Getting the car back to how it ran when the factory had it was always the priority for 2023 so a richer needle B1BF often used in the Stag was fitted and the car was taken to Dave Boggs rolling road in North Yorkshire to see where we were.

Not enough fuel; at higher rev’s speeds and problems with the butterfly valves in the throttle flaps. Having said that, it was much quicker than it had been on the drive home.

MARCH 2023

Butterfly valves removed and replaced with TR4 throttle flaps (no valves – seen in the plastic bag with the removed ones for comparison) and the richest needle Stromberg still make B24081was fitted and a return to Dave Boggs for the end of March 2023.

This time we got what we were looking for and quite a bit more than I had thought we were going to get – 217bhp. How ever we knew there was a serious issue with the distributor and the advance curve plus the needles still weren’t right so after a distributor with the correct advance curve fitting, plus rebuild and needles hand profiled we tried again in September 2023.

SEPTEMBER 2023

This time we clocked the road at 270bhp. So as that was at the wheels we estimate when the factory had the car it would have been close to 300bhp at the flywheel.

OCTOBER 2023

On October 6/8th 2023 Both TR8’s completed the Round Britain Reliability Run 43 years on from when the factory first did the run in 1980.

This is a condensed version of the 48hr run shown from both TR8’s NWK988W and MHP404V’s POV over the 48 hrs.

December 2023

The original Lockheed 4 pot callipers and vented discs were refitted to the car (removed to protect the 1980 originality for the RBRR 2023 run and temporarily replaced with newer versions, which are now fitted to my other LHD TR8) having all been reconditioned and painted to preserve them for the next 40 plus years

FEBUARY 2024

While the original discs were being skimmed, we had them laser measured and have since had brand new disc castings individually recreated, by the company who made them for AP Racing originally. This time to a much higher standard than the originals as well as double heat treated to prevent warping under extremes

MARCH 2024

Mileage for NWK988W in March 2024 was 23,062 from new! Quite a significant jump up in mileage, but only because we clocked up 3k plus miles on the Club Triumph Round Britain Reliability Run in October 2023 on its own, plus quite a few other events in 2023, such as the TR8 Day/Weekend at Gaydon.

Club Triumph Annual Dinner March 9th 2024 to celebrate the 2023 RBRR. We had commemorative awards created in the same style as the original awards from 1980. Tim in the middle is holding the original award from 1980.

APRIL 2024

One thing we didn’t change when we got the car (and should have) was the shocks as they felt fine, however doing the round Britain really pushed them.

What we found was the original front struts were found to be leaking oil, one very badly so definitely needed replacing. I imagine once I started using the car hard on the RBRR the dry rubber seals simply cracked and they started leaking.

As the rear originals were the blue adjustable SPAX.

and the front modified Armstrong’s which as a company was taken over by Monroe, I decided on SPAX as they were still around and still made adjustable versions to fit the TR8. Problem now is there are only a tiny handful of companies who make shocks for these cars now, so choice is very limited unless you start swapping out the front struts for the works car struts which would of course then make it unoriginal from what was done originally, even though that wasn’t factory original, if that makes sense.

See https://www.spaxperformance.com/classic-products/gas-adjustable-dampers/

The rear shocks were found to be jammed in the fully hard position and that probably explains Richard Hurdwell’s reaction to the suspension being harder when I gave him a quick spin round Gaydon in 2022 when I first got the car.

I think if I remember rightly, when we got back, he thought it might have been the 15” wheels I moved the car to, causing the hard ride.

Someone had tried to adjust them at some point in time but only succeeded in breaking the adjusters on both sides. My plan originally had been to count the adjustment clicks and transfer the settings to the new adjustable shocks, but that idea was now out of the window given no adjusting clicks to count. Tried a few settings, fully soft was very sloppy and bouncy, so the springs appeared to be doing a lot of the work, and 75% hard was knock your teeth out on just a cat’s eye. So, after quite a few trials and errors I’m currently running at 16/18 on a scale of 28 (100% locked hard) possible adjustable clicks.

Settings on the car currently that seem to be a decent compromise

57% = Front 16

64% = Rear 18

Trial and ERRORS

Front fine Rear still a little hard with road holding not quite so well but softer ride.

57% = Front 16

69% = Rear 19

Front fine, Rear hard but holds road really well with tyres squealing on roundabout turning hard in

57% = Front 16

71% = Rear 20

Front a tiny bit hard but rear softer than front

60% = Front 17

60% = Rear 17

Front and rear too hard knock your teeth out on a speed hump

75% = Front 21

75% = Rear 21

Front and Rear too SOFT by a long way.

17% = Front 5

17% = Rear 5

MAY 2024

The stereo we converted to a Pioneer period fascia running a hidden Bluetooth amp but once again the RBRR separated the men from the boys with so many numerous odd usb charging issues on the run that in the end we just left my phone doing satnav permanently. I had gone that route originally because of the limited space behind the centre consol. How ever, time moves on and Pioneer have a few models now that are only half the depth. After a little filing on the consol edges, the cage and Pioneer MVH-330DAB made a very good fit. 1980 Period speakers are still fitted.

Bumped into Derek Mathewson at Thornton-le-dale show Sunday May 26th where I was pleased to put him straight and give him a few pointers on genuine factory RHD TR8’s. He will be running away as fast as his legs can carry him if he sees me again, but at least he knows what a genuine factory RHD TR8 is now!

Unfortunately, on getting home and parking up the peddle suddenly went to the floor and I was unable to select any gears.

Oddly enough the fluid had changed colour to green so assuming the seals had gone the master and slave were swapped out. Didn’t fix the problem and the slave pin has an odd motion of turning when you moved it. So, nothing for it but to take the clutch apart.

We had thought the pin might have gone through the fork so a new reinforced fork (plate welded over the pin area and so it can’t go through) and uprated clutch were purchased.

Turned out one of the fork slippers was missing. Possibly been missing for a while given the way the gearbox was a bit odd at times when selecting gear. It seems without a slipper on both sides the pin eventually jumped out of the slot on the release bearing hence the problem. Only a small piece, yellow circle but it cost a lot of time trouble and work to fix. Still this clutch should be good for the life of the car now finger crossed!

JUNE 2024

The seat trim has long been a let-down for an otherwise immaculate interior given the foam behind the velour dries to a powder and drops out leaving saggy seats. I’ve asked many trimmers over the years but either they wanted the seats for months, or they don’t want to deal with 44 years old velour. June 2024 I finally found a trimmer who promised to turn the seats round in an unbelievable two days, and did! Gave the original carpets a good scrub while the seats were out and they came up like new as the car hasn’t seen much sun in its life.

Original velour trim cleaned with new foam behind the velour to replace the old foam that had dried out over 45 years.

The door panels and other trim coloured pink by the sun I had previously changed/vinyl painted in 2023 so now the whole interior looks like new!

JULY 2024

Suspension settings on the car currently that seem to be a decent compromise and have been fine tuned a bit from previously.

57% = Front 16

57% = Rear 16

Coming back from the Inter Club show at Malvern I felt some vibration in the steering at 60/70 so had the front wheel bearings replaced (still has the original ones fitted so probably wise to change anyway) and steering, exhaust, gearbox and engine mounts all checked out to see if the cause can be found. Tracking was also being checked for alignment. Gearbox mounts squishy so needed changing and may as well change engine mounts as well given while they looked ok they are 44 years old.

I have used Lanoguard for many years on all my TR’s and this car is no exception, more so as I wanted to preserve the car as it was when I got it and Richard Hurdwell left it, so the clear coating is useful to see the modifications he did easily.

Looking for the spring hose P clips (AAU7374) for sometime to finish the engine off as some of the originals broke when I took them off in 2022. Amazing how it often just takes one small item to really finish something off, but that small something, is NLA and almost impossible to find! The autojumble at Newby Hall was where I finally found some.

SEPTEMBER 2024

Suspension settings on the car currently that seem to be a decent compromise and have been fine tuned a bit from previously. Lot of trial and error but we are just about there now.

54% = Front 15

57% = Rear 16

MARCH 2025

Mileage for NWK988W in March 2025 was 23,958 from new!

JUNE 2025

When the car was initially put up for sale after the death of the first owner his wife sent it to a local garage on the Isle of Man to be made road worthy given it a stood for around 40 years and so it could be sold. They unfortunately only did enough so the car ran so I have a lot of work later still to sort out. But one observation on their final bill that always stood out to me was the car needed new rear springs due to unequal ride hight. As I knew from Richard Hurdwell the springs had been made individually at the time, and he didn’t know what the rating was I’d left it until now.

I contacted a company in Sheffield who said they could measure the current ones and make some new ones to exactly the same spec as the originals. The data they came up with was as follows.

One spring had after 45 years sagged slightly and there was some degrading from what was estimated to be the original spec of around 205 lbs with a height of close to 9 inches representing a lowering of 1.5 inches against the original standard springs.

I ran round with some uprated 195 lb springs in place of the originals while the originals were away and I noticed the suspension was back to rocking again, so back to messing with the SPAX settings. Surprisingly going lower actually made the car start to feel more neutral as it did when I first got it. In other words, no obvious over or understeer. Slight wobble on some bumps but once the new springs were fitted it was pretty much perfect!

Settings on the car June 2025 that seem to be pretty much perfect!

42% = Front 12

42% = Rear 12

NWK988W is now probably as close to when it left BL MOTORSPORT as it has ever been since it left. Sadly, previous owners didn’t know what they had, only ever noticing the car had different uprated brakes. Thanks to Garry Owen the manager responsible for the RHD TR8’s emailing me the BL MOTORSPORT modifications memo – some 30 years ago, I did. It’s taken 3 years to get the car back from the various detuning mistakes of previous owners to where it was meant to be, but finally I think we are there!